FRP & Aluminum Custom Living Habitats for Expedition Vehicles

We manufacture each Boxmanufaktur box individually according to your requirements and suitable for your base vehicle.

Since we manufacture the sandwich panels for our boxes ourselves, we are able to laminate in GRP profiles for flaps and doors or metal frames in the floor. This increases the stability and minimizes the body height. Reinforcements for rear carriers, awnings, floor rails or seat systems with belts can also already be taken into account when pressing the sandwich panels.

For increased torsional rigidity, we recommend that some interior walls and furniture components also be made of sandwich panels.

We plan and manufacture the subframe at the same time, if desired.

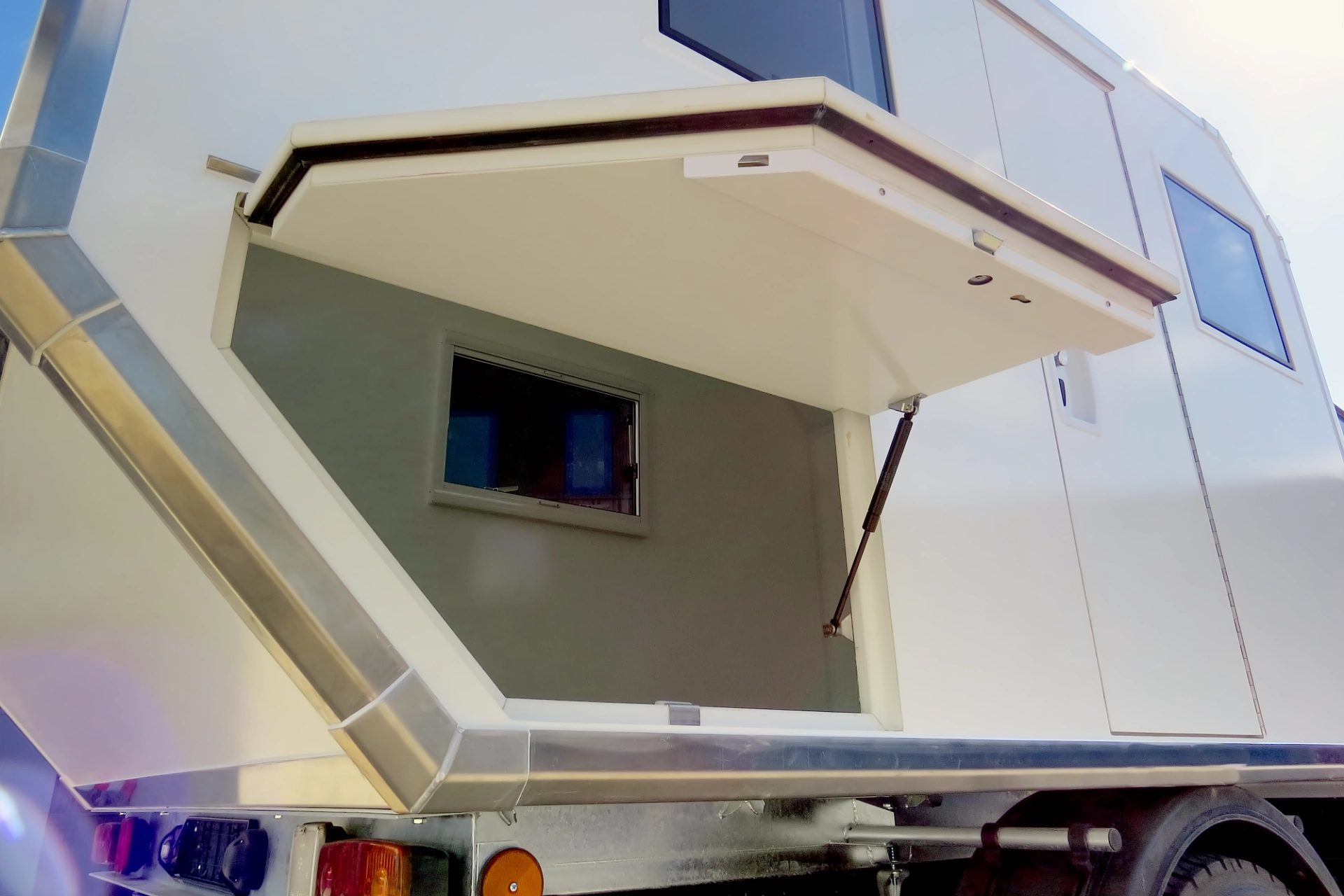

Customized underfloor storage boxes made of GRP or stainless steel, roof racks and rear lift solutions round off the overall appearance of the vehicle and create additional storage space.

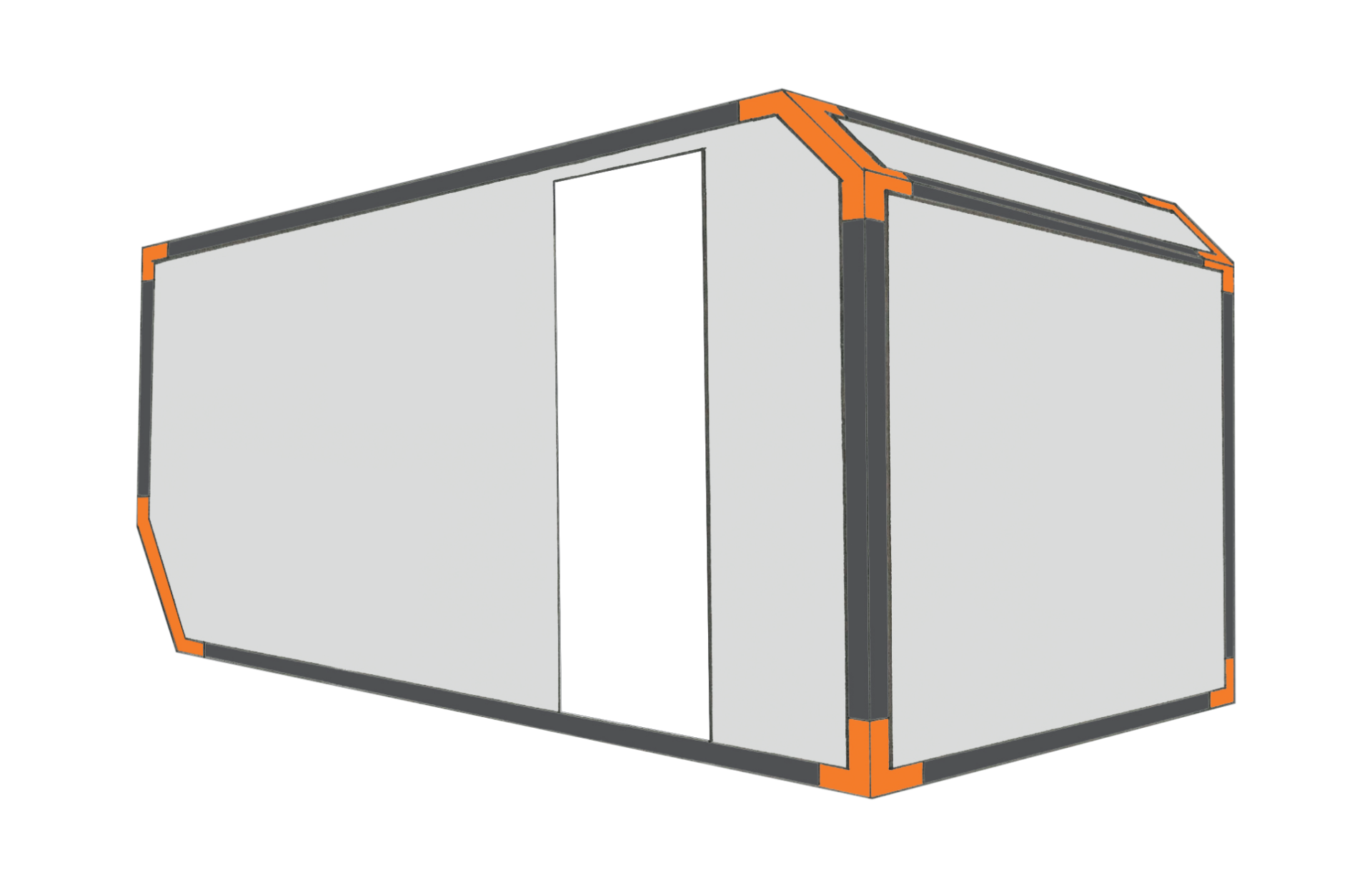

All Boxmanufaktur boxes have been developed for off-road use and are therefore perfectly suited as living habitat for expedition vehicles, 4×4, overland vehicles, and off-road vehicles of all sizes such as e.g.

Ultra-light FRP top layers and a wall strength starting at 42 mm make the Light Box the first choice for expedition vehicles based on e.g. Mercedes-Benz Sprinter, Ford F350 & F450 or Unimog U 1300.

Our Base Box or Light Box do not meet your requirements? The Individual Box offers you a free choice of top layers, wall thicknesses, shapes, dimensions, etc.

As we all know, the details make all the difference. But what makes the Boxmanufaktur cabins so special? What makes the Boxmanufaktur cabins different from others?

For the construction of your box, we use only individually manufactured sandwich panels from our own production. This allows us almost unlimited possibilities in the implementation of your wishes and personal requirements. From ultra light to extra strong – Different FRP laminates or even 1.2mm aluminum are used depending on the weight and robustness requirements.

Reinforcements can be partially pressed in behind the top layers for easy and secure mounting of e.g. furniture, awnings or airline rails.

Integrated reinforcement frames in the rear wall allow easy attachment of bicycle racks and lightweight spare wheel holders.

Underfloor heating can be optionally integrated in the floor panel.

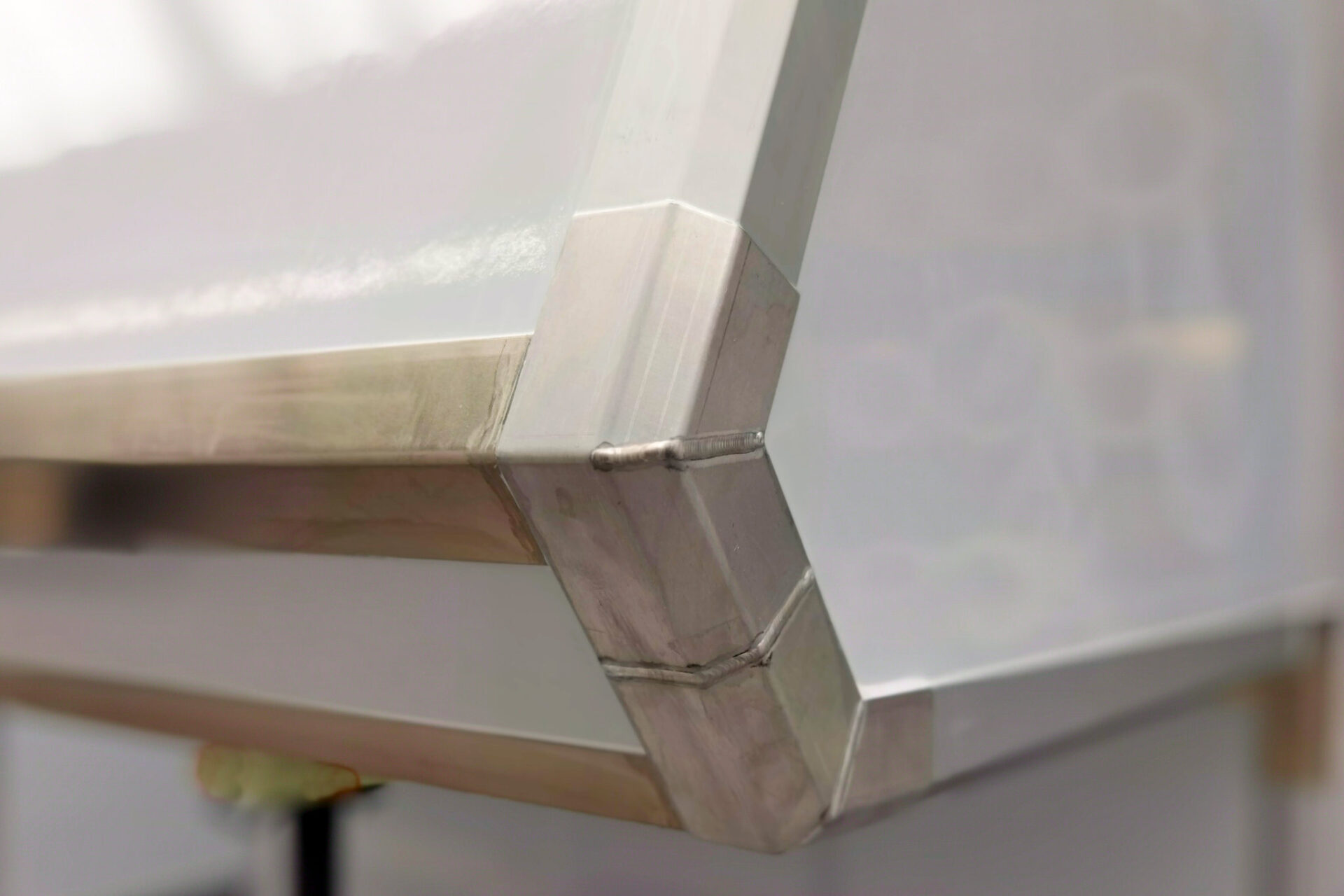

Complex nested corner joints with maximum adhesive surface ensure enormous stability of your Boxmanufaktur booth. The 4 mm thick aluminum profiles and the additional corner caps, also made of 4 mm aluminum, enclose the cabin all around and increase the stability of the cabin again significantly. At the same time, the 45° beveled aluminum profiles protect the cabin e.g. from passing branches or brushwood.

Access between living cabin and

driver's cab. With one or two

passage doors and

custom-made bellows.

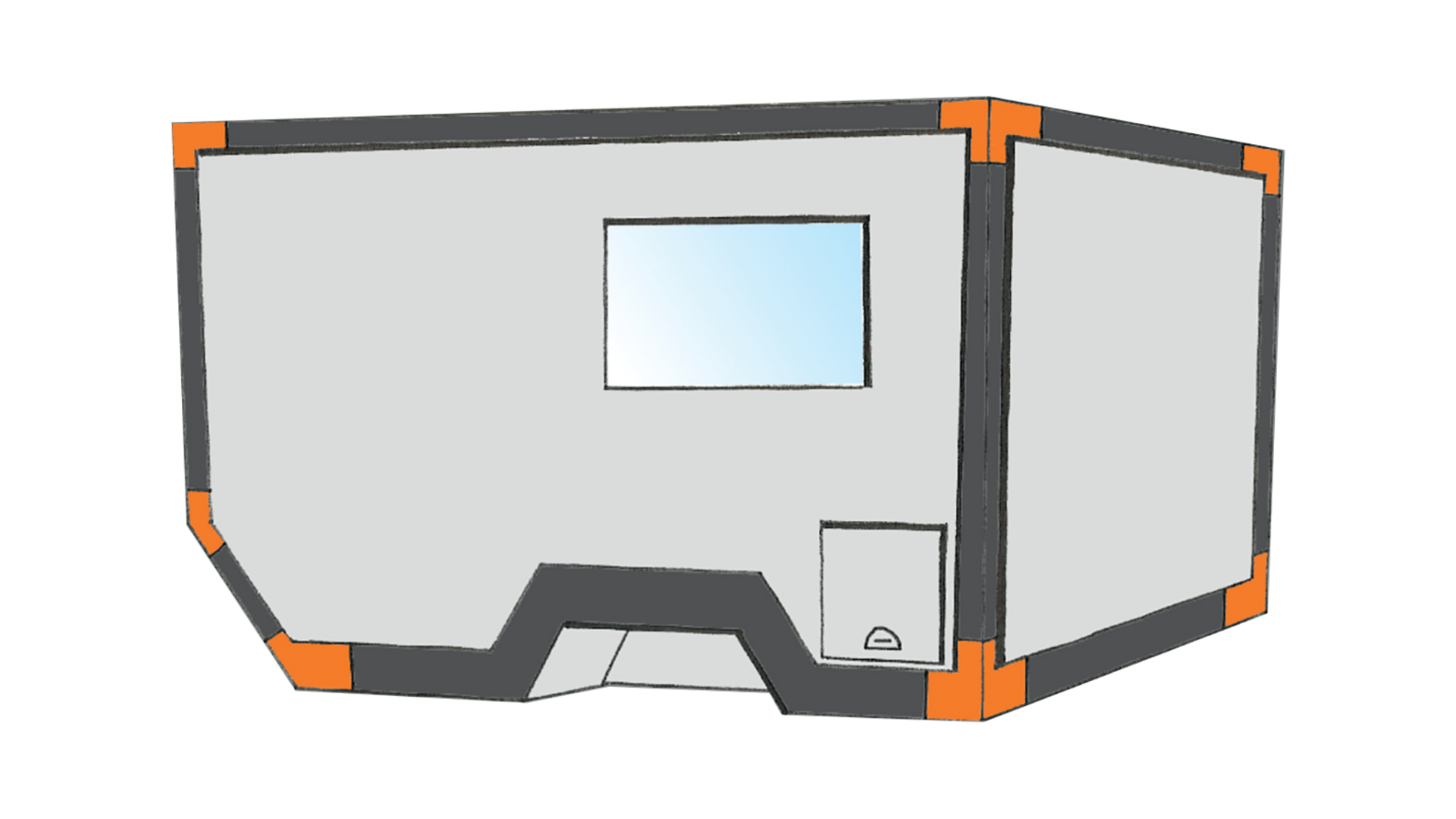

Windows, skylights and hatches from KCT, Outbound & Dometic Seitz

Front or rear sloping,

overcab with double bed, or

as additional storage space.

Our doors and hatches are made of the same material as the composite boxes and are fully wall integrated during production of our composite sandwich panels. The doors and hatches thus have the same insulation value as the walls and, thanks to the identical surface, blend in perfectly with the cabin design. The 3-point locking system with lever handle set and piano hinge made of stainless steel round off the first-class workmanship and close the doors and hatches securely and tightly.

For secure mounting of the box on the sub frame, the cold-bridge-free Boxmanufaktur floor assembly is equipped with integrated aluminum profiles. Alternatively, the sub frame can also be integrated directly into the floor assembly.

Choose from a wide range of additional options.

from FRP sandwich panels

We optionally equip your box with intermediate floors and interior walls made of FRP sandwich panels. These not only provide additional stiffening of the box, but are also ideal for separating the bathroom & shower from the living area due to their moisture resistance. The construction of a double floor for the center of gravity-optimized installation of e.g. water tanks or heavy technology is also possible. Very popular is also a garage partition made of FRP sandwich panels to the living area, e.g. with integrated round seating group, dinette or as a platform for your bed.

Tempered glass and acrylic windows for your expedition vehicle

For your composite RV box, we use high-quality double-glazed windows and roof hatches from KCT and Outbound. Acrylic windows from Dometic Seitz are also available for our weight-optimized boxes.

You would like to install the windows yourself? That is also possible. We make the required cut-outs in the cabin walls for you, accurate to the millimeter, and deliver the desired windows, skylights and hatches at the same time.

The foundation for your composite box

The subframe is probably the most underestimated component of an expedition vehicle. Here, the subframe literally plays a supporting role in the construction of your vehicle.

In most cases, the frame of a truck is designed to be able to twist. The torsional capacity ensures that all wheels can maintain contact with the ground and that the load is optimally distributed. In order for this to continue to function despite an installed box, a subframe is necessary, which on the one hand establishes the connection between the vehicle and the box but at the same time prevents the torsional forces of the chassis from being transferred to the box and damaging it.

Taking into account the base vehicle, we plan together with you which mounting concept is suitable for the planned area of application.

The following subframe mounting concepts are available:

Assembling the box on the base vehicle

Your Boxmanufaktur box is ready and will now be mounted on the base vehicle. Before we hand over the vehicle to you and you can start building your expedition vehicle, we carry out a final interlocking test to ensure that everything fits and the subframe sufficiently decouples the box from the chassis.

From the empty box to the ready-to-travel expedition vehicle

We turn your box and your base vehicle into an expedition vehicle ready to travel – individual, self-sufficient, safe.

Contact

In 3 Schritten ihr Angebot anfordern